What Are The Advantages And Disadvantages Of Activewear Manufacturing Different Processes?

- Share

- Issue Time

- Nov 10,2020

Summary

Our purpose of writing this article is to enable business owners in the activewear market to better understand the advantages and disadvantages of different manufacturing processes.

What Are The Advantages And Disadvantages Of Activewear Manufacturing Different Processes?

Our purpose of writing this article is to enable business owners in the activewear market to better understand the advantages and disadvantages of different manufacturing processes. Custom activewear knows which technology they want. If you are interested in learning more, please keep in touch. Let's continue browsing.

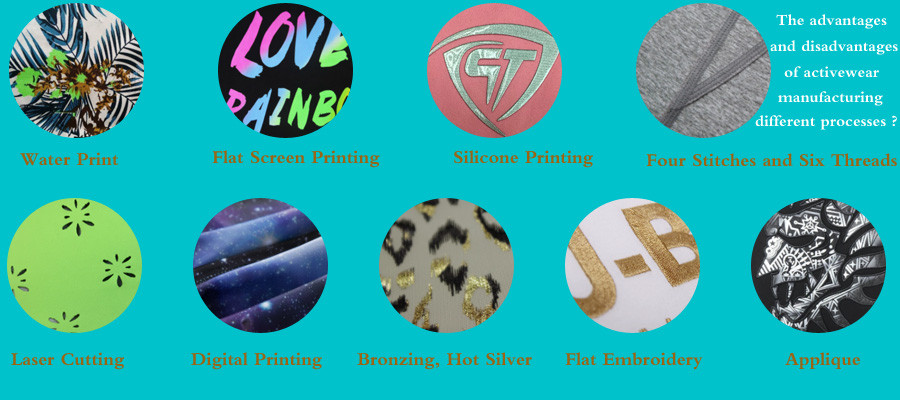

1. Four needles and six threads

Four needles and six threads, namely ISO607 stitches, consist of four upper threads, one bottom thread and one broken thread. It is mainly used for the connection of seams and has the advantages of beautiful, straight and similar seamless. It has a unique high elasticity, flatness and high-strength stitching effect, so it is widely used in high-end sportswear, yoga clothing, and underwear.

2. Laser cutting

Laser cutting can achieve fabric accuracy without touching the fabric, which means that the garment will not be contaminated during the manufacturing process. At the same time, it can perfectly realize your complex patterns. For sportswear, it can be used to dig holes in sports bras, tank top , shorts and yoga pants, which can improve product quality.

3. Flat screen printing

Advantages: exquisite design, reflective and difficult to wash off, low cost

Disadvantages: long viscous time, poor air permeability, poor level, unable to print very fine patterns

4. Digital printing

Advantages: fine patterns, generally do not fade; non-sticky, non-reflective, and the air permeability of the matte surface is better than that of screen printing

Disadvantages: no layer, slightly more expensive than screen printing, color accuracy is slightly worse than that of screen printing.

5. Silicone printing

Advantages: strong three-dimensional

Disadvantages: single color, usually silver gray, poor air permeability, and expensive

6. Hot stamping, hot silver, hot paper

Advantages: special effects can be achieved

Disadvantages: airtight, expensive

7. Watermark

Advantages: feel very soft, non-reflective, delicate patterns, cheap, good air permeability

Disadvantages: the color is not bright enough to be printed on dark clothes, only light colored clothes

8. Flat embroidery

Advantages: strong three-dimensional effect, good gloss

Disadvantages: expensive, uncomfortable to wear

9. Decals

Advantages: strong sense of layering, bumpy

Disadvantages: very expensive

Fengcai gym wear factory is a chinese activewear manufacturer with rich production experience. We can provide you with wholesale and customized services of activewear. If you want to find the wholesale trend of activewear? Please contact us for discounts for bulk orders.

Contact information:

E-mail: admin@hcsportswear.com

+8613602338395